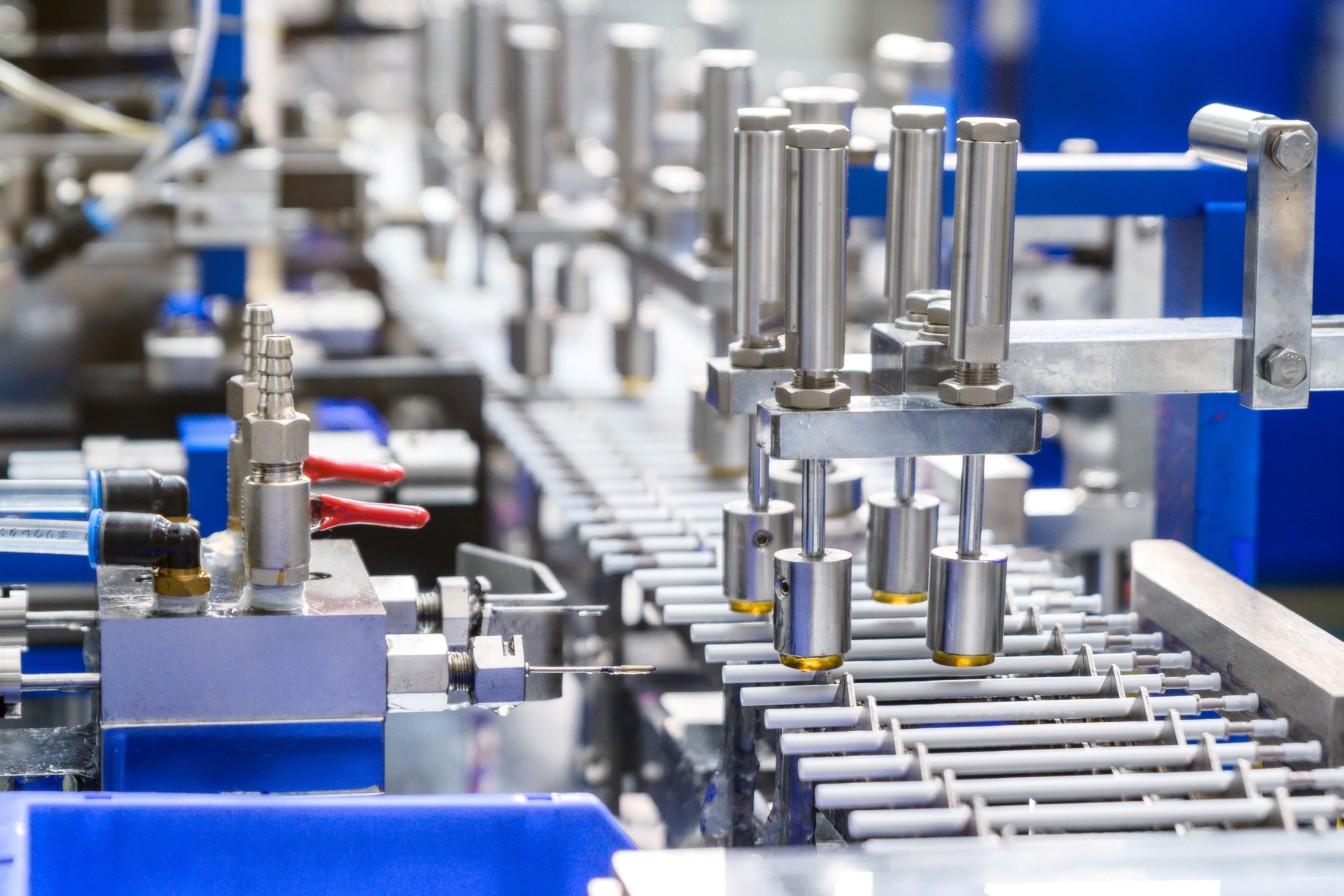

Enhancing automation

AUTOMATION

Thien Long focused on researching, self-designing, and manufacturing machinery and equipment for use in production. The group also promoted designing and manufacturing molds to replace imported ones in order to reduce product costs and improve production capacity and competitiveness.During the year, the group made many renovations to adapt to the market situation and increase the automation rates in its factories. The year saw many high-productivity automatic technology lines put into operation, along with hot runner molds and plastic multi-component molds. The group mastered precision mechanical technologies to continue manufacturing pen tips with Swiss and German machinery and equipment. It has invested in and applied energysaving injection machines with high accuracy. The automation rate at South Thien Long was raised to 81.38% compared to 78.86% at the end of 2021. As a result, the Group’s overall productivity has been increasingly improved.

GREEN TECH

Since its establishment, Thien Long has considered the GREEN factor as one of the top criteria in its operation. Accordingly, the group has developed a standard wastewater treatment system that does not cause environmental pollution while saving energy and raw materials.

Emissions to the environment are deducted by 1,326 ton CO2/year. Solar power system product 1,548,146 kWh/year.

STRICT QUALITY MANAGEMENT SYSTEM

Emissions to the environment are deducted by 1,326 ton CO2/year. Solar power system product 1,548,146 kWh/year

ISO Certifications

Medical Device Quality Management System - ISO 13485:2016

Ensure that medical devices and equipment adhere to standards for quality and user safety.

Laboratory Management System - ISO 17025:2017

Control laboratory competence to assure result correction.

Quality Management System - ISO 9001:2015

To satisfy customer’s demands, ensure quality of materials, production processes and finished products.

Environmental Management System - ISO 14001:2015

Control and mitigate environmental pollution, meet legal requirements

Social Accountability System - SA 8000:2014

Control child labor, forced labor, salaries, working hours, policies, occupational safety

International Council of Toy Industries – ICTI

To ensure that toys are manufactured in a safe and humane environment